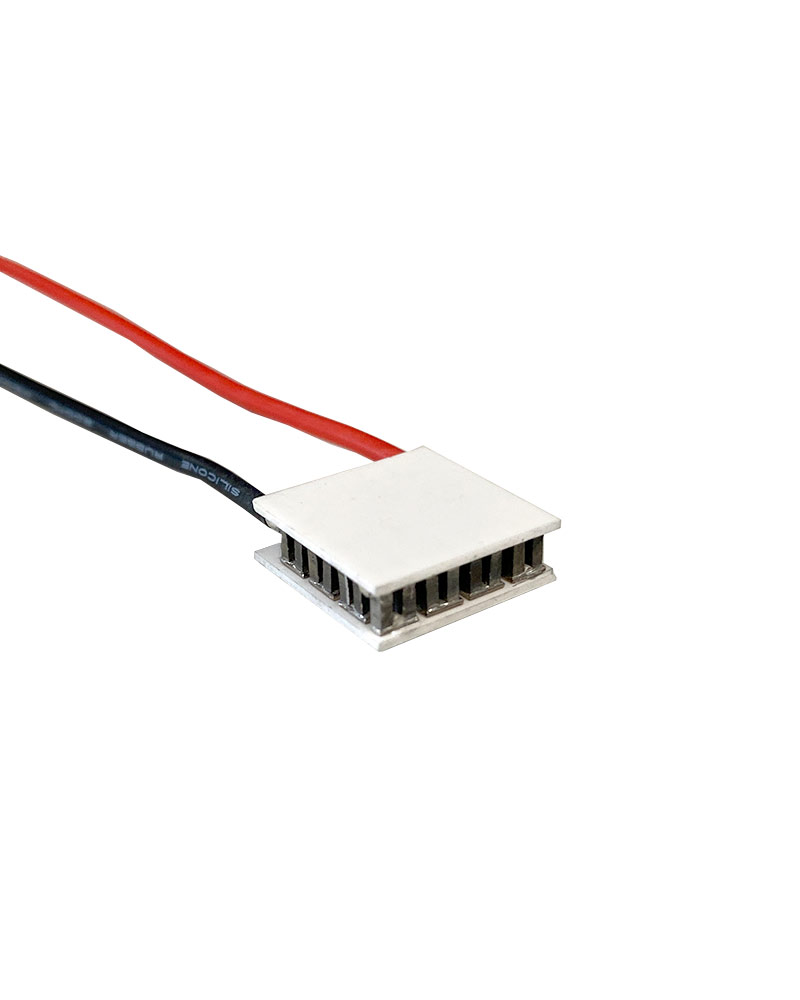

Switch cabinets sometimes contain very sensitive electronics. Controls, switching units, computer technology etc. All these electrical devices guarantee the smooth running of a wide range of processes in industrial manufacturing, data centers, small businesses and large factories. And they are becoming more and more obligatory, as increasing automation and the ever-growing aspect of artificial intelligence, which after all has to get its power from somewhere, increases the importance of well-functioning control cabinets.

If you look at a control cabinet from a distance and break down all its functions, all the small contacts, every single resistor, every semiconductor to the essentials, then a control cabinet is nothing more than a small cosmos that works entirely on its own and, under the right conditions, ensures that all its tasks are performed smoothly and correctly. Of course, these conditions range from correct installation and the right power supply to sufficient space and safety in the control cabinet and the right temperature control in the control cabinet – a subject area in which the most diverse opinions circulate.