DNPT Adds the New TEC Controllers to Its Portfolio!

Modular, precise, powerful, and scalable – temperature management that pushes boundaries.

We are proud to announce the launch of our latest innovation: the DNPT TEC controllers — a response to the growing demands for precision, performance, connectivity, and integration in thermoelectric systems. Building on decades of expertise and close collaboration with our customers, these controllers offer exceptional flexibility for a wide range of applications where maximum accuracy, stability, and process control are essential.

Our goal: Thermal excellence in every application

Our TEC controllers benefit from nearly 70 years of expertise at Dr. Neumann Peltier-Technik GmbH in the field of thermoelectric technology. They are designed not only for current developments in active, coolant-free temperature control but, thanks to their flexibility, also for areas that do not yet exist today.

At the same time, they already perform everyday tasks within our systems with reliability and precision.

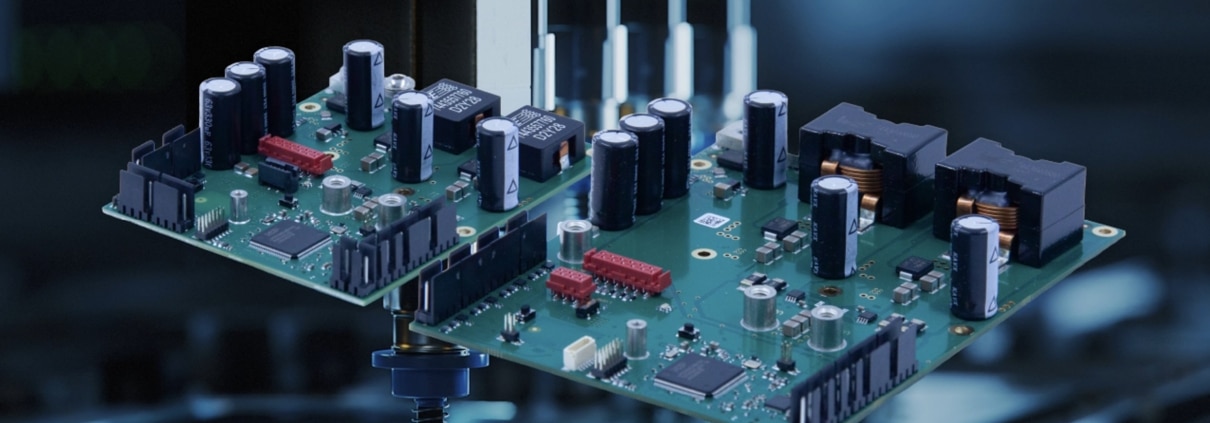

The PWR-CTRL System

At the heart of the DNPT TEC Controllers are the Peltier modules, which we also supply. Developed in Germany and manufactured within the EU, our controllers are available in three performance levels (XS, M, and L, ranging from 150 to 1,500 watts of Peltier output power) and offer:

- Outstanding temperature stability: Our PWR-CTRL systems achieve temperature stability and precision of up to ≤ 0.01 K – essential for critical applications in medical technology, analytics, and precision manufacturing.

- Consistent power output:A precise output current with a ripple of less than 1% increases the lifespan and efficiency of your Peltier elements.

- High integrability: Integrated GPIOs enable versatile control of both the controller itself and its peripherals. This opens up a wide range of customization and integration options to meet specific application requirements. This opens up a wide range of customization and integration options to meet specific application requirements.

- Precise measurements: A 24-bit dual ADC enables highly accurate temperature measurements using Pt100, Pt1000, AD590, or NTC sensors, ensuring you always maintain full control over your thermal processes.

- Seamless peripheral integration: PWR-CTRL TEC controllers come with integrated drivers for peripheral components, allowing fans, pumps, signal transmitters, and, for example, level sensors to be connected directly without additional effort. level sensors to be connected directly without additional effort.

- Industry standards: With our plug-on accessory boards, communication is available via UART, RS232, RS422/485, and USB. With our COMM-PRO communication extension, additional interfaces such as REST API and a web server are provided. For direct control, a 2.83″ membrane keypad or a touchscreen of the same size can be used. Additional boards include a DC/DC converter, an I²C/Aout board, and a PWR/Aout module.

Our priority: Giving you complete control over your application.

Our TEC controllers feature active and continuous monitoring, providing you with complete control over your temperature control application. Thanks to the built-in SD slots, data logging is also possible. The integrated autotuning function provides regulation perfectly tailored to your specific application—without the need for manual, time-consuming fine-tuning.

Multiple sensors, such as temperature probes, monitor your system at various points, giving you a complete overview of its current status. High-resolution temperature sensors (PT100 or PT1000) precisely measure the target variable to be temperature-controlled. You can choose which sensor should serve as the control reference and position them wherever best suits your application.

For critical processes as well: Absolute safety and reliable fallback mechanisms

Even perfectly designed systems can be exposed to faults or disturbances. To ensure you can quickly take control in such cases, a multi-level warning system—fully configurable for your specific application—is integrated.

All critical functions—both within temperature control and monitoring, as well as all peripheral connections—can be equipped with warning and safety shutoff triggers. This ensures that even in critical situations, you maintain full oversight and can respond quickly to setup errors or external disturbances—without risking prolonged downtime.

Networking and communication: COMM-PRO for intelligent systems

Peltier applications are complex and often interconnected. While standalone TEC controllers provide the foundation for precise temperature control, they do not offer a user-friendly or seamless system integration.

We know there’s a better way!

The COMM-PRO communication module takes the DNPT TEC controller to the next level, enabling seamless integration into modern, connected environments:

- Remote Control: With the integrated web server and REST API, users can control and monitor the system remotely—ideal for distributed setups or hard-to-reach installations.

- Multi-node management: A key feature of the COMM-PRO module is the ability to monitor and control up to 16 interconnected nodes. This enables efficient management of complex thermoelectric systems, such as those used in the temperature control of medical reactors.

- Data logging: The real-time clock and file system enable seamless 24/7 data recording with a capacity of over one year, ensuring comprehensive analysis and documentation of thermal processes.

- Touch display: The COMM-PRO module supports a 2.83-inch touch display, allowing direct control of up to 2 nodes—perfect for laboratory settings or field service applications.

For applications that require limited communication capabilities or no HMI, our PWR-CTRL TEC controllers can also be paired with specialized, compact, and cost-optimized communication modules. Standard serial protocols are available by default, such as: RS232, RS485 or RS422.

Modular architecture for maximum flexibility

DNPT TEC controllers feature a modular design, complemented by a wide range of accessories and interface boards. This allows you to tailor the system precisely to your needs and create the optimal solution for your specific application.

Application areas

DNPT TEC controllers are ideal for a wide range of applications:

- Analytical instruments: Precise temperature control is essential for accurate and reliable measurements or analytical processes, such as PCR testing. We use these controllers ourselves in our chiller products and test rigs.

- Medical technology: For cooling medical devices and in point-of-care diagnostics.

- Industrial automation: For temperature stabilization of lasers, optical systems, and electronic components. They are also used in conjunction with industrial robots.

- Telecommunications: For cooling sensitive components in compact telecommunications systems, such as in satellite communications.

- Research and development: For experiments requiring highly precise, loggable, and reproducible temperature control.

DNPT TEC controllers represent more than just an improvement—they signify a paradigm shift in thermoelectric control technology. Contact us today to discuss your requirements and discover how the TEC controller can optimize your applications!

More information will soon be available on our website.