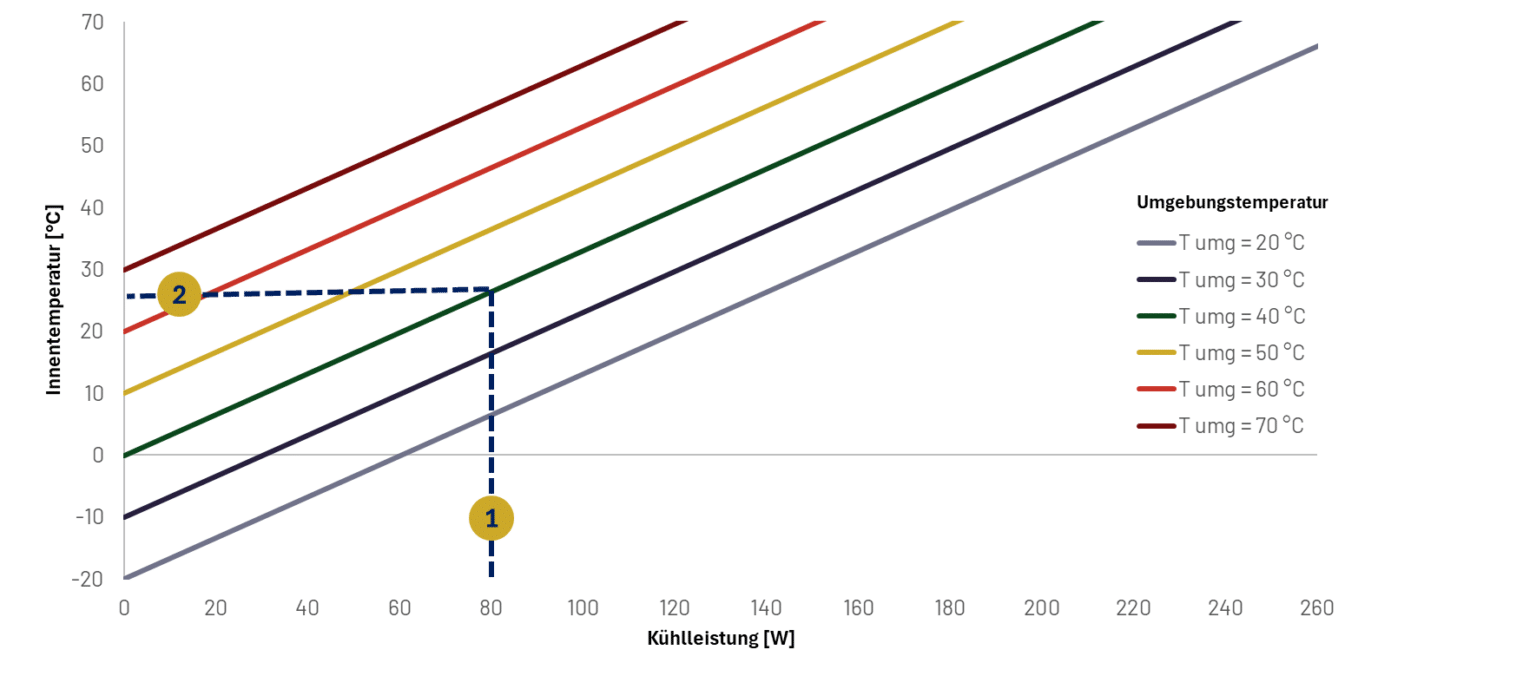

Control Cabinet Cooling: Preventing Excessive Heat Build-Up

When a control cabinet overheats, it can shorten the lifespan of components, cause system failures, and compromise compliance with standards. That’s why the temperature rise limits specified in DIN EN (IEC) 61439 must be strictly observed. This article walks you step by step through how to realistically assess the thermal conditions, accurately calculate the power losses inside the cabinet, and determine the actual cooling or heating requirements. You will also learn when control cabinet cooling becomes necessary and how to systematically select suitable solutions—such as those based on Peltier technology.